- The Column

- Posts

- 🏭 Fischer-Tropsch 2.0

🏭 Fischer-Tropsch 2.0

Making jet fuel with CO2 and H2 and more polypropylene in Indonesia

Good morning. Air Company's process is probably the most interesting thing I've ran into in a while. If you have the time I recommend reading their white paper (linked below) and getting back to me with your thoughts on its feasibility.

From the condenser:

· Making jet fuel with CO2 and H2

· More polypropylene in Indonesia

· POTD: vinyl records

Using CO2 and H2 to make jet fuel

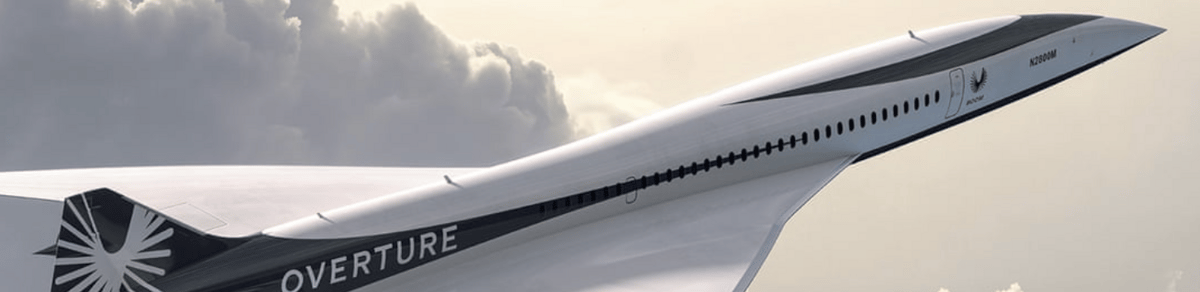

CO2-utilization start-up, Air Company, has announced plans to produce sustainable aviation fuel (SAF) from CO2 and green hydrogen.

First, a little background on SAF:

Due to energy density requirements, using batteries for planes isn't as feasible as using them for cars. So, currently, the only viable method of reducing the emissions associated with aviation is to use a sustainably-sourced feedstock (instead of petroleum). That's why the Inflation Reduction Act heavily incentivizes SAF production (up to $1.75 per gallon in tax credits) and why we're seeing a bunch of companies attempt to make kerosene look-a-likes. For example, we've talked about LanzaJet wanting to convert ethanol to SAF, Gevo wanting to do it with isobutanol, Velocys using Fischer-Tropsch synthesis, and plenty of other companies using vegetable oils (here's one example).

Okay, now some context on CO2:

CO2 is a very thermodynamically stable molecule (it's at the bottom of the oxidation ladder), which is sort of like saying that it's rather non-reactive. That doesn't mean you can't react CO2 to form other molecules—it's just that the reactions or separations downstream don't usually make good economic sense (notable exceptions include the production of urea and polycarbonate polyols). Anyways, recently we've seen Celanese, Sumitomo, and Perstorp all working on methods to hydrogenate CO2 to make methanol, which is actually pretty similar to what Air Company is trying to do.

Bigger picture:

At a glance, Air Company's website is full of bold claims and pretty marketing, which is rare for a chemical company. Sometimes that can be a red flag, but the white paper on their process is reassuring. The company is looking to displace the century-old Fischer-Tropsch process (which uses carbon monoxide and hydrogen) with their new process (which uses carbon dioxide and hydrogen). It's success hinges on a proprietary catalyst that suppresses the formation of methane and olefins in favor of short chain alcohols (methanol, ethanol, and n-propanol) and C8-C18 alkanes (which is similar to the composition of kerosene, hence the SAF announcement). Those products are easier to separate via distillation which bodes well for the economic piece of the puzzle.

W.R. Grace & Co are bringing PP to Indonesia

Indonesian petrochemical company, PT Kilang Pertamina International (PT KPI), has selected W. R. Grace & Co's polypropylene (PP) technology for a new site in East Java, Indonesia.

Some context:

We've been making PP for quite some time now—the first production process was brought to life in tandem with some controversial catalyst development in the late 1950s. The production of PP rapidly expanded as the patent-holders licensed the process to various operating companies across the globe. Today, by a confusing mess of mergers and acquisitions, four companies now license (slightly) different ways of making PP: W.R. Grace & Co, Lummus Technology, Ineos, and LyondellBasell.

So, what's the deal?

This new site headed to East Java is going to be home to a naphtha cracker, a 1 million ton per year high-density polyethylene plant, and a 600,000 ton per year PP plant. That process technology for that new PP plant, expected to start up in 2024, will be licensed by W.R. Grace & Co (FWIW, they call their process Unipol).

Zooming out:

The takeaway here is really just a scale reminder. W.R. Grace & Co has licensed its Unipol process out to roughly 60 plants and LyondellBasell has done it for over 150 plants (including a new plant in Indonesia announced last January). Even though new PP sites aren't springing up left and right in the West, tons of these plants are still being built in the East (and let's not forget about Africa).

Some more headlines:

INEOS just sold the first of its recently launched propylene glycol ethers

37 chemical companies agreed on a way to calculate carbon footprint

Apparently China increased its crude oil imports from Russia

AmSty signed an agreement to buy Encina's plastic-waste-based aromatics

The US Senate voted to reduce the production of hydrofluorocarbons

Product of The Day:

Today, we're breaking down vinyl records.

Despite "vinyl" not being a real material, the abbreviated name actually describes what these things are made of pretty well. Typically, the thermoplastic resin used to produce vinyl records is mostly (between 75-96%) a blend of polyvinyl chloride (PVC) and polyvinyl acetate (PVA) alongside various other additives such as heat stabilizers, lubricants, dyes (because PVC and PVA are clear), and plasticizers.

PVC is made from vinyl chloride monomer (VCM) from ethylene dichloride (EDC). PVA is made from vinyl acetate monomer (VAM). If you react ethylene, oxygen, and chlorine you get EDC. Swap that chlorine for acetic acid and you get VAM.

In case you're interested:

Tip: Add Lustre to your browser so you can see price history and reviews before buying anything online.*

Book: The Alchemy of Air is a must-read for anyone interested in the chemical industry. It's the story behind the Haber-Bosch process that lead to fertilizer—and explosives.*

Podcast: Check out this episode featuring Dr. Tina Tosukhowong of PTT Global Chemical on her career and stance on sustainability.

Video: Are you still a student? Give Shawn Esquivel's video on the most important skills to learn a watch.

The bottoms:

All views represent those of the author not their employer.

Reply